Overhead Linesworker NOS Units

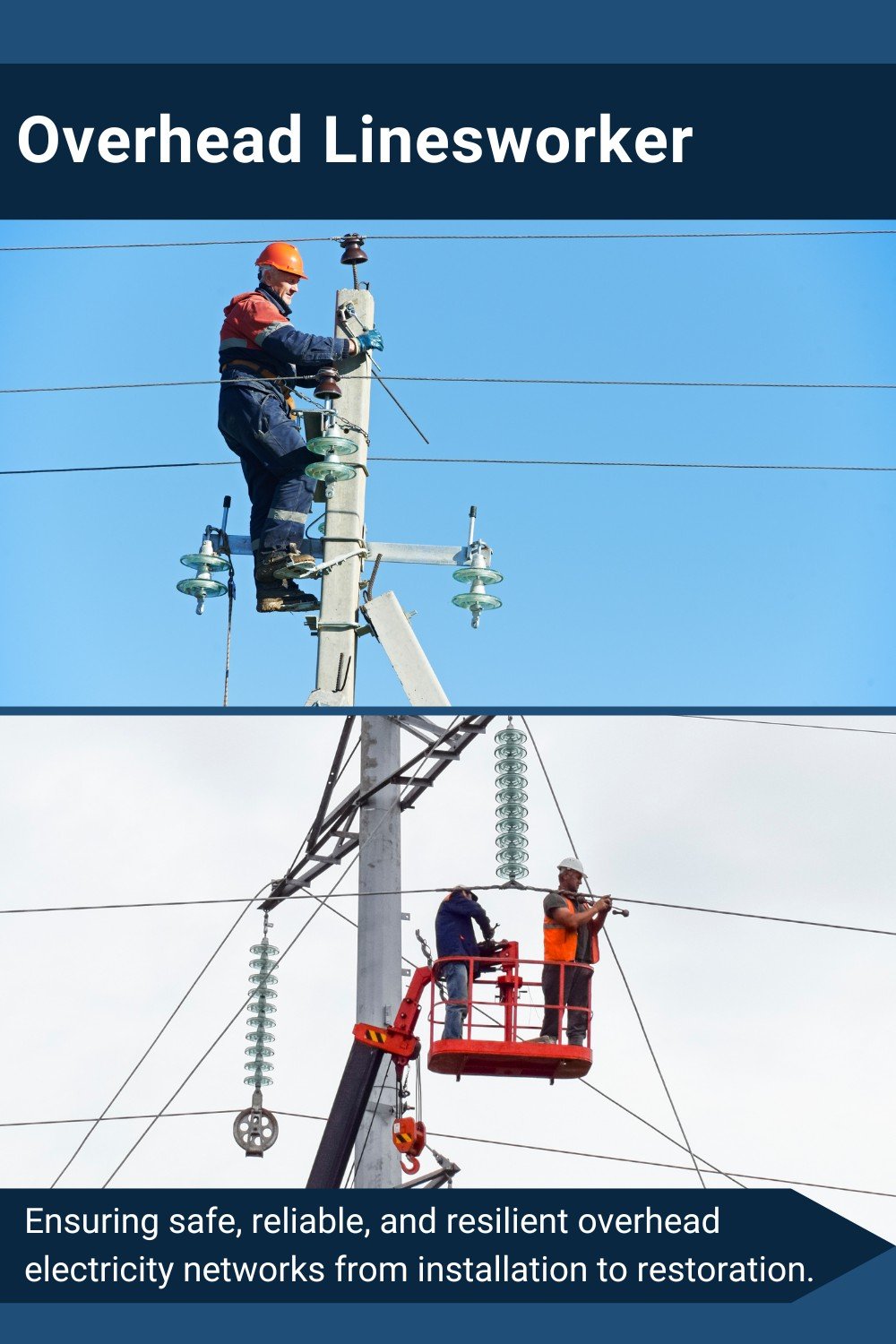

Overhead Lineworkers play a critical role in delivering safe, reliable, and resilient electricity networks. Working across distribution and transmission environments, they install, maintain, inspect, and restore overhead line infrastructure that supports communities, industry, and essential services. The occupation demands high levels of technical precision, safety discipline, environmental awareness, and the ability to operate confidently within authorised limits in both routine and emergency conditions.

The following NOS units for this occupation develop the applied technical, safety, and operational competencies required for modern overhead line operations. The units cover essential areas including isolation and permit systems, structural erection, conductor installation and termination, inspection and maintenance, fault investigation, network restoration, environmental protection, documentation, and operational communication. Together, they prepare Overhead Lineworkers to support network reliability, maintain compliance with safety and environmental standards, respond effectively to faults and outages, and contribute to the secure and efficient operation of the electricity grid.

CLICK on ANY of the LINKS Below and Download for FREE. You are welcome to amend any of the PDFs. If you want the MS Word version, get in touch.

NOS Units

Unit 1 Apply Isolation, Earthing, Grounding, and Permit-to-Work Procedures: Covers the application of electrical isolation, earthing, grounding, and permit-to-work systems to establish and maintain safe working conditions during overhead line activities.

Unit 2 Use Tools, Lifting Equipment, PPE, and Testing Instruments Safely: Addresses the selection, inspection, and safe operation of tools, lifting equipment, access systems, testing instruments, and personal protective equipment.

Unit 3 Interpret Execution Drawings, Line Profiles, and Sag Data: Develops the ability to interpret approved drawings, line profiles, and sag data to prepare accurately for installation and maintenance work.

Unit 4 Confirm Work Locations with Supervisors and Survey Information: Ensures accurate confirmation of pole and tower locations, site layouts, and work boundaries through coordination with supervisors and survey data.

Unit 5 Access Poles and Towers and Apply Fall-Prevention Measures: Enables safe access to overhead line structures using approved systems while applying fall-prevention measures and monitoring site conditions.

Unit 6 Erect Poles and Towers and Install Structural Components: Covers the erection of poles and towers and installation of structural components to achieve alignment, stability, and load security.

Unit 7 String, Tension, Sag, and Secure Overhead Conductors: Provides competence in pulling, tensioning, sagging, and securing conductors to meet specified mechanical loading and clearance requirements.

Unit 8 Terminate and Secure Conductors and Line Hardware: Addresses the installation and securing of dead-end assemblies, clamps, compression joints, bonding systems, and associated hardware to ensure mechanical strength and electrical continuity.

Unit 9 Inspect Overhead Line Structures, Conductors, and Components: Covers systematic inspection of overhead line assets to evaluate condition and classify defects within authorised limits.

Unit 10 Perform Planned and Corrective Maintenance on Overhead Line Systems: Enables execution of preventive and corrective maintenance to maintain structural integrity and reliable network operation.

Unit 11 Investigate and Assess Overhead Line Faults: Develops analytical capability to evaluate fault indications, assess associated risks, and determine corrective actions within authorised limits.

Unit 12 Repair or Replace Damaged Components and Support Supply Restoration: Covers the repair or replacement of damaged components and verification of readiness to support safe and controlled restoration of the electricity supply.

Unit 13 Control Waste, Prevent Pollution, and Reinstate Work Sites: Addresses implementation of environmental protection measures, waste control, pollution prevention, and site reinstatement following operational activities.

Unit 14 Complete Work Records and Maintenance Documentation: Covers accurate recording of operational activities, inspection findings, and maintenance actions within approved documentation systems.

Unit 15 Communicate Hazards, Findings, and Work Progress to Supervisors and Teams: Develops clear communication of hazards, technical findings, and work progress to support safe coordination and timely escalation.